Industrial water plays a crucial role in the modern industrial system. It is a fundamental element for the smooth operation of industrial production, and almost all stages of a product—from raw materials to processing and shaping—cannot proceed without water. Generally speaking, industrial water includes not only water used in the production process but also domestic water for employees within the factory area.

This paper will analyze the classification, water quality and pretreatment requirements of industrial water use, discuss the corresponding pollution control technologies and recycling approaches, and provide references for enterprises to seek better industrial water services.

Why Should We Understand Industrial Water Use?

Industrial water projects are not only related to the quality and efficiency of industrial production, but also closely linked to environmental protection and the sustainable use of resources. The United Nations World Water Development Report 2024: Water for Prosperity and Peace points out that issues related to water availability and water quality pose risks to industry, which may lead to supply chain disruptions. This directly affects the development of industry (and the economy). Reducing water demand and harmful wastewater discharge can achieve a win-win situation in water resource protection and water pollution control.

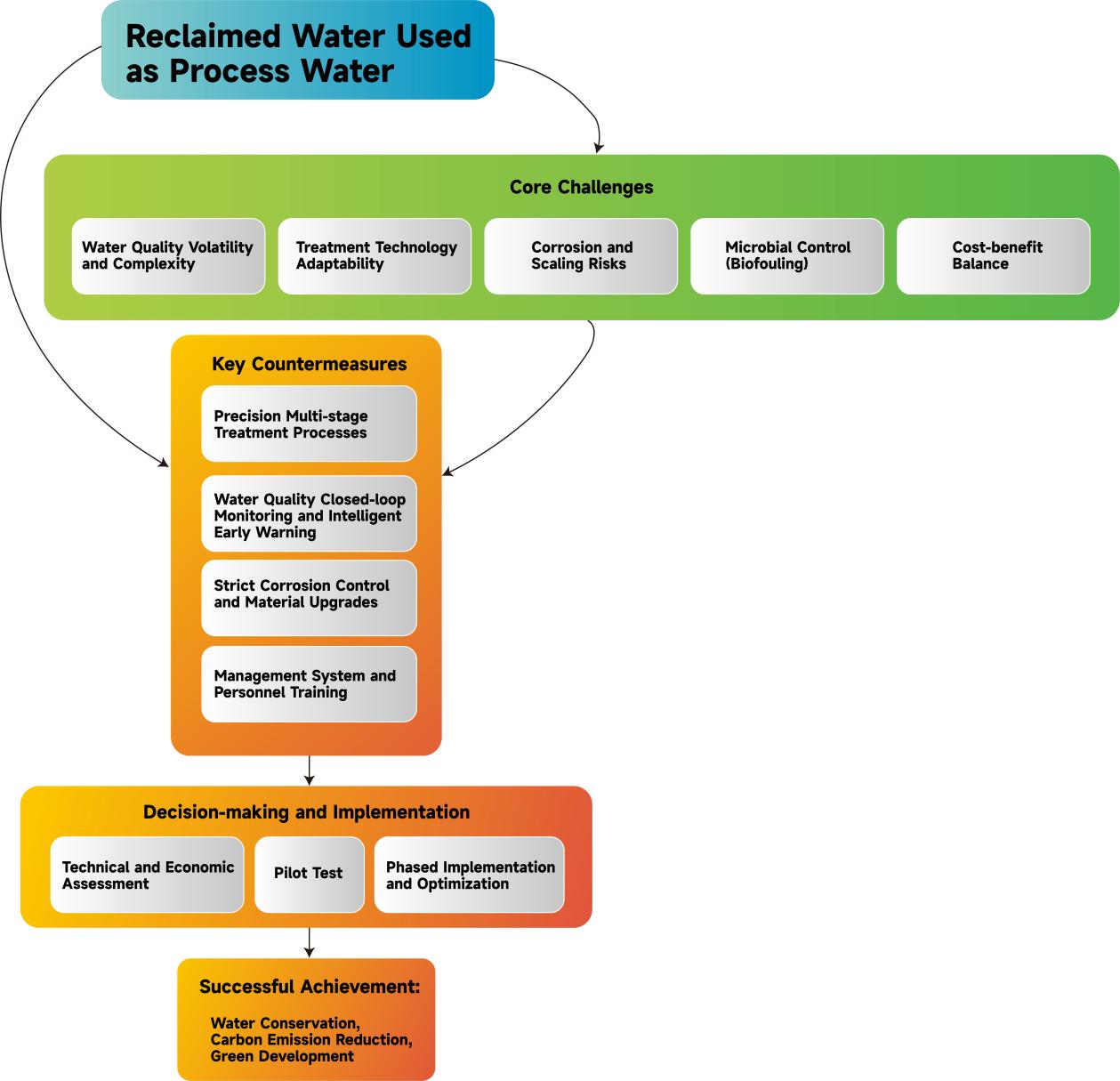

As the traditional water resource development model has approached the ecological red line, the reclaimed water reuse industry has quietly emerged. It has become an important supplement to the industrial water system and promotes the transformation of industrial water use from linear consumption to a closed-loop cycle. Through advanced water treatment technologies, wastewater is treated to meet the water quality standards for industrial water and then reused in industrial production. This not only greatly eases the pressure of water resource shortage but also significantly reduces the water use costs of industrial enterprises.

What is Industrial Water Use? What are Its Classifications?

Industrial water refers to the general term for water used in manufacturing, processing, cooling, air conditioning, washing, boilers, and other aspects during the industrial production process by various departments of industrial and mining enterprises, as well as domestic water for employees within the enterprises. In terms of sources, industrial water mainly comes from surface water, groundwater, tap water, seawater, recycled water, and other water sources, which are collectively called “raw water”. After treatment, raw water is converted into softened water, demineralized water, pure water, ultrapure water, etc. Within some industrial enterprises, water is often classified according to its specific uses and water quality. For example, there is mashing water in the beer industry, neutralization and decolorization water in the monosodium glutamate industry, and ash flushing water in the thermal power industry.

1.What is Production Water?

Production water refers to water directly used in industrial production. It includes indirect cooling water, process water, and boiler water.

2.What is Indirect Cooling Water?

In the industrial production process, indirect cooling water refers to the cooling water used to absorb or transfer excess heat from production equipment to ensure the equipment operates at a normal temperature.

3.What is Process Water?

In industrial production, process water refers to the water used for manufacturing and processing products, as well as water related to the manufacturing and processing processes. It includes product water, washing water, direct cooling water, and other types of water.

4.What is Boiler Water?

Boiler water is a general term for water used in boilers that generate steam for industrial processes, heating, or power generation, as well as water used for boiler water treatment. It includes boiler feed water and boiler water treatment water.

5.What is Domestic Water?

Domestic water is a general term for water used by employees for daily life in factory areas and workshops, as well as miscellaneous water for other purposes.

What are the Water Quality Indicators for Industrial Water? How to Test?

When the same cup of water flows into a steel plant in Germany’s Ruhr region and a textile factory in India’s Gujarat, it must comply with completely different “rules for use” — and industrial water quality standards are the concrete embodiment of such rules.

Application scenarios, regional differences, and regulatory interactions determine that there are significant differences in water quality requirements across different regions and industrial sectors. For example, the semiconductor industry has extremely high requirements for water purity, needing to remove various ions and organic substances from water to ensure the production quality of electronic components. In contrast, the papermaking industry has relatively lower water quality requirements, focusing mainly on the content of suspended solids and organic matter in water. Even for ultrapure water, the food industry places greater emphasis on microbial control and limits for chemical pollutants, and its indicators are far less strict than those of the semiconductor industry.

The water quality of industrial water is closely related to the level of economic development. Developed regions such as the United States, the European Union, and Japan have more advanced industrial water treatment technologies and generally implement higher water quality standards. For example, regarding ultrapure water, the American standard ASTM classifies water with a resistivity of over 18.1 MΩ·cm into three grades based on the theoretical limit of ultrapure water resistivity (18.3 MΩ·cm), namely Type E-1, Type E-1.1 (the standard currently achievable by most semiconductor manufacturers), and Type E-1.2.

The classification of pure water grades embodies the combination of standardization and specialization. However, the imbalance in global water quality standards is not only a reflection of technological gaps but also a microcosm of different stages of economic development.

Industrial water testing and management are usually the responsibility of enterprises themselves. Enterprises need to conduct real-time monitoring and control of various indicators during the water treatment process to ensure the stable operation of water treatment technologies.

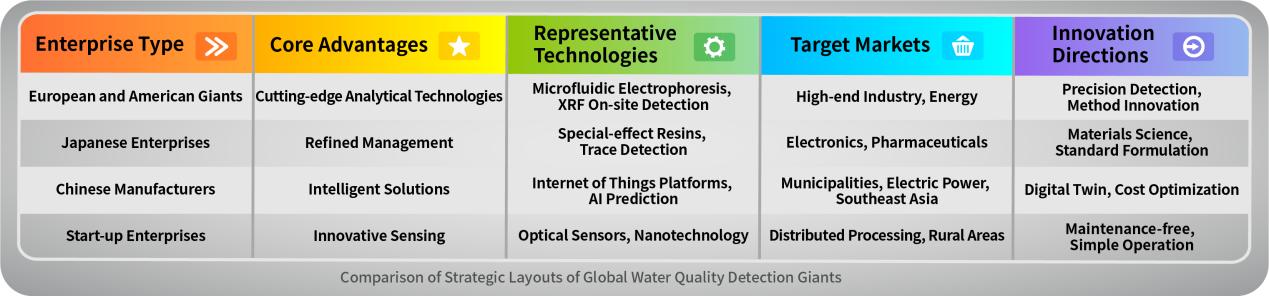

Currently, the field of industrial water quality testing is undergoing a transformation in technical paradigms, evolving from traditional offline laboratory analysis to online monitoring, real-time early warning, and intelligent decision-making. This transformation is driven by the integration of multiple disciplines such as sensor technology, microfluidic chips, spectral analysis, and artificial intelligence, which significantly improves testing efficiency and data value.

How to Treat Industrial Water Use?

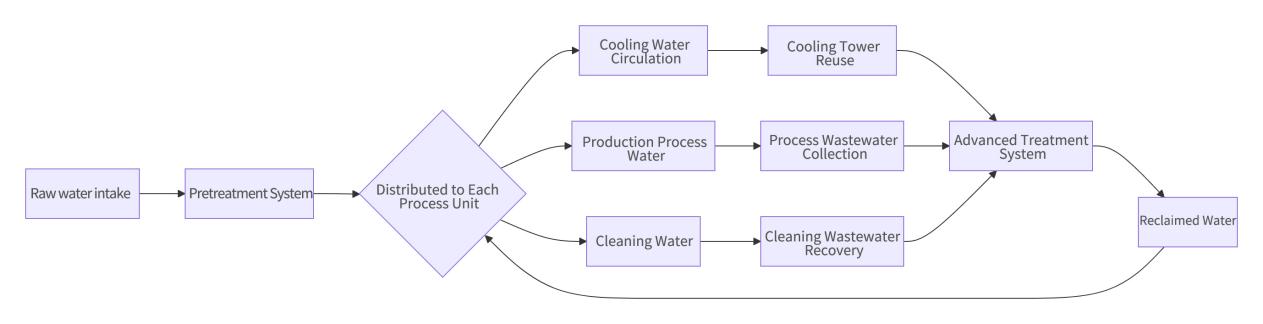

Industrial water has strict requirements, and industrial wastewater has become one of the main sources of water pollution. Centering on the core goals of “raw water purification” and “wastewater treatment”, industrial water treatment can be divided into five core modules: the pre-treatment stage, the production process water treatment stage, the circulating cooling water treatment stage, the production wastewater treatment stage, and the reclaimed water treatment stage. Each module has clearly defined functions and treatment objectives.

The pre-treatment stage serves as the “first line of defense”. It conducts preliminary treatment on raw water to prevent system blockages, corrosion, or contamination, aiming to provide qualified raw material water for industrial production. The production process water treatment stage carries out “customized purification” to meet the core needs of production.

The goal of the production wastewater treatment stage is to achieve compliant discharge and reduce environmental risks. The circulating cooling water treatment stage requires extensive use of cooling water to cool down equipment, and it is necessary to prevent equipment failures caused by poor water quality.

Finally, the pre-treatment discharge water, circulating water discharge water, and production wastewater that has met discharge standards undergo comprehensive treatment. This process enables the water to meet the “reclaimed water standards” and be reused in non-core production links, forming a closed-loop water resource system. This is also the core direction of industrial water conservation at present.

The Core Technological System for Industrial Reclaimed Water Treatment

At present, industrial water treatment processes are mainly divided into physical, chemical, biological, membrane separation, and other methods according to their technical principles and treatment stages. These methods are usually used in combination to deal with complex water quality.

1.Physical Treatment Technology

Physical treatment technology separates suspended impurities, colloids, or some soluble substances in water by utilizing the physical properties of materials, without damaging the molecular structure of pollutants. It usually uses quartz sand, activated carbon, ultrafiltration membranes, and other materials for filtration and screening, separates suspended solids by gravity or centrifugal force, and balances fluctuations in water quality and quantity through water tanks or equalization tanks. The advantages of physical treatment lie in low energy consumption and simple operation, but its effect on removing soluble pollutants is limited, so it is usually used as a pre-treatment stage.

2.Chemical Treatment Technology

It achieves purification by adding chemical agents to break the chemical bonds of pollutants or change their existing forms. For example, adding agents such as polyaluminum chloride (PAC) and polyacrylamide (PAM) can destabilize tiny colloids and aggregate them into large flocs, making it easier to remove them through sedimentation or filtration. Adding sodium hypochlorite, ozone, or using ultraviolet (UV) rays can kill microorganisms. Chemical treatment technology takes effect quickly and has high efficiency, but it may cause secondary pollution, so the dosage of chemical agents must be strictly controlled.

3.Biological Treatment Technology

Relying on the metabolic activity of microorganisms, it converts pollutants such as organic matter, nitrogen, and phosphorus in water into carbon dioxide, water, and other substances. The anaerobic-aerobic combined process is the mainstream technology for treating low-toxicity, high-organic-matter wastewater. Pollutants like COD and BOD are removed through aeration tanks and biological filters, reducing the load of subsequent chemical treatment. Biological treatment technology has low costs and stable operation, but its effect on refractory organic matter is limited, so it usually needs to be used in combination with other processes.

4.Membrane Separation Technology

Membrane separation technology mainly includes microfiltration, ultrafiltration, nanofiltration, reverse osmosis, and other processes. It has advantages such as high separation efficiency, low energy consumption, no secondary pollution from chemical agents, and stable effluent quality. As a core technological pillar for the preparation of electronic-grade ultrapure water, membrane separation technology runs through four major stages: “pretreatment → primary desalination → advanced desalination → terminal refinement”. Compared with traditional processes, it offers higher purity, more stable operation, and lower energy consumption. However, it has relatively high investment costs and prominent membrane fouling issues, requiring regular cleaning and maintenance.

5.Electrochemical Water Treatment Technology

As a highly promising emerging process in the field of industrial water treatment, electrochemical water treatment technology removes pollutants directly or indirectly through redox reactions on the electrode surface. It has advantages such as mild reaction conditions and no secondary pollution, and exhibits high efficiency in treating refractory and highly toxic pollutants. For instance, in coking wastewater treatment, the electro-heterogeneous ozone catalytic technology can increase the TOC removal rate to 1.5-2.6 times that of ozone oxidation alone. However, due to its relatively high energy consumption, it is still mainly used for the enhanced removal of specific pollutants at present.

| Treatment Technology | Principle | Advantages | Limitations |

|---|---|---|---|

| Physical | Filtration, sedimentation | Low energy, simple | Limited for soluble pollutants |

| Chemical | Coagulation, disinfection | Fast, effective | Possible secondary pollution |

| Biological | Microorganism degradation | Low cost, stable | Ineffective for refractory pollutants |

| Membrane Separation | Pressure-driven filtration | High purity, no chemicals | High cost, fouling issues |

| Electrochemical | Redox reactions at electrodes | No secondary pollution, high efficiency | High energy consumption |

What Technologies Help Achieve the Circular Reuse of Industrial Water?

Through continuous innovation, the recycling of industrial water has developed an integrated treatment model of “membrane technology + advanced oxidation + biological enhancement + intelligent control”.

1.Core Innovation Direction: Membrane Technology

By utilizing the selective permeability of membranes, water molecules or target solvents in industrial water pass through membrane pores under the action of driving forces such as pressure and concentration difference, while impurities in the water—including salts, organic matter, heavy metals, and suspended solids—are retained. This achieves water purification and recycling. The pore size and surface charge characteristics of membranes determine their retention capacity.

At the NEWater plant for Changi wastewater treatment in Singapore, reclaimed water is further purified through advanced membrane technology and ultraviolet technology, reaching drinking water standards. The reverse osmosis section in the plant adopts an energy recovery system, saving 4,000 kWh of energy per day and realizing efficient and energy-saving reclaimed water treatment.

2.Treating Refractory Organic Matter: Advanced Oxidation Technology

In scenarios such as drinking water disinfection, printing and dyeing wastewater decolorization, and in-situ groundwater remediation, advanced oxidation technology can generate reactive species like free radicals with strong oxidizing properties (mostly hydroxyl radicals ·OH). Under reaction conditions including high temperature and pressure, electricity, sound, light irradiation, and catalysts, it oxidizes macromolecular refractory organic matter in water into low-toxic or non-toxic small-molecule substances. This purifies the water quality, enabling it to meet the standards for recycling and reuse.

Due to its strong ability to degrade biochemically recalcitrant organic pollutants, advanced oxidation technology has become a research hotspot in the industry. Its main methods include ozonation, Fentonoxidation,electrochemical oxidation, photochemical oxidation, sonochemical oxidation, and catalytic wet oxidation. Among them, the electro-heterogeneous ozone catalytic technology achieves a TOC removal rate 1.5-2.6 times and 1.4-5.8 times higher than that of ozonation alone for printing and dyeing wastewater and pharmaceutical wastewater, respectively.

3.Enhancing Treatment Efficiency: Bionic Filtration System

The bionic filtration system is a major innovative direction for improving the efficiency of industrial water recycling. It can simulate the filtration, adsorption, and degradation functions of organisms in nature. By artificially constructing filtration units with bionic mechanisms, it forms a technical system that achieves advanced purification of reclaimed water. Its core lies in combining natural purification principles with engineering technology to enhance pollutant removal efficiency and system stability, and pollutants are ultimately degraded into harmless substances.

It usually consists of three core units working in synergy: the bionic interception layer for pretreatment, the core bionic biological filter layer, and the advanced purification adsorption layer. Compared with traditional filtration technologies, its core competitiveness lies in the efficient simulation of natural mechanisms, featuring low operating energy consumption, strong impact resistance, and environmental friendliness.

4.Future Development Direction: Smart Water Utilities

Embedding AI into the key links of reclaimed water treatment helps form closed-loop management and achieve multiple goals, including improved treatment efficiency, reduced energy consumption costs, and stable effluent quality. For example, the AI toxicity early warning system deployed by Suez Group in a petrochemical park in France identifies 0.1 ppm-level heavy metal pulse discharges through spectral characteristics, shortening the response time to 15 minutes.

In reclaimed water treatment, AI is expanding from the optimization of a single link to the intelligent management and control of the entire process. Its core lies in enabling the shift of reclaimed water treatment from experience-driven to data-driven through data-driven perception, analysis, decision-making, and regulation. It has become a key technical support for improving the efficiency of reclaimed water utilization and promoting water resource circulation. The Digital Water Innovation Summit—held during WATERTECH China—brings together AI-focused experts and showcases live demos and pilot projects in smart water management.

Last Words: Industrial water management is a systematic project that requires the joint efforts of the government, enterprises, and various social sectors. By establishing scientific water management systems, promoting the application of advanced water-saving technologies and reclaimed water utilization technologies, and strengthening water resource protection and water environment governance, the sustainable development of industrial water can be achieved, providing strong support for the sustainable development of the economy and society.

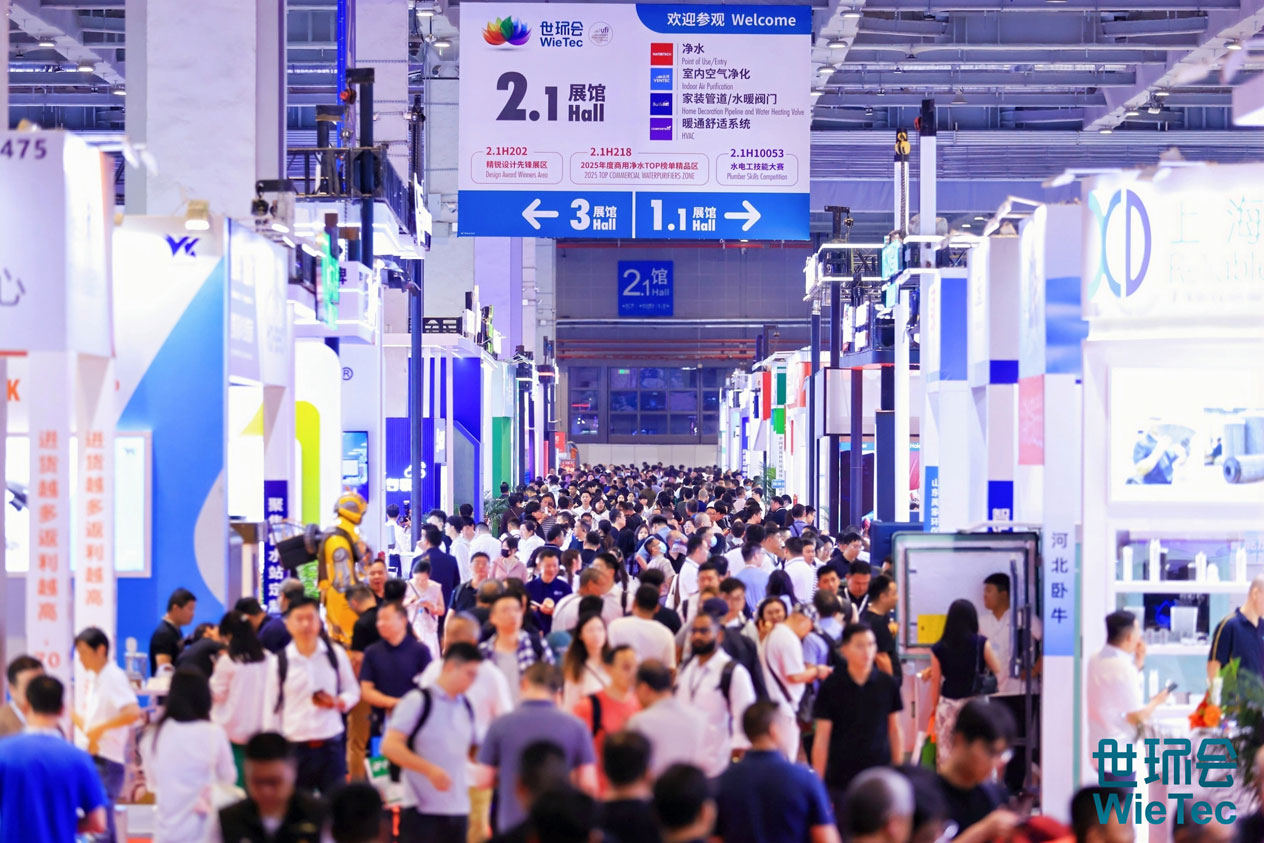

Looking to see these technologies in practice or connect with experts? WATERTECH China—a leading industry platform—hosts major exhibitions such as the Shanghai, Guangzhou, and Beijing Water Shows. These water industry events bring together top water-tech companies, real-world case studies, and digital innovations across industrial recycling, AI-driven monitoring, membrane systems, and more. Attending or following updates from these shows can offer hands-on insights and valuable networking opportunities.

Reference:

1. United Nations Educational, Scientific and Cultural Organization. (2024). The United Nations World Water Development Report 2024: Water for Prosperity and Peace. UNESCO.

2. ASTM International. (2013). D5127-13: Standard Guide for Ultra-Pure Water Used in the Electronics and Semiconductor Industry. ASTM.

3. Baker, R. W. (2012). Membrane technology and applications (3rd ed.). John Wiley & Sons.

4. Lee, K. P., Arnot, T. C., & Mattia, D. (2011). A review of reverse osmosis membrane materials for desalination—Development to date and future potential. Journal of Membrane Science, 370(1-2), 1–22.

5. Miklos, D. B., Remy, C., Jekel, M., Linden, K. G., Drewes, J. E., & Hübner, U. (2018). Evaluation of advanced oxidation processes for water and wastewater treatment – A critical review. Water Research, 139, 118–131.

6. Martínez-Huitle, C. A., & Brillas, E. (2009). Electrochemical alternatives for drinking water disinfection. Angewandte Chemie International Edition, 48(30), 5612–5626.

7. Rajeshwar, K., Ibanez, J. G., & Swain, G. M. (1994). Electrochemistry and the environment. Journal of Applied Electrochemistry, 24(11), 1077–1091.

8. Haxton, T., Kapelan, Z., & Savic, D. (2020). Artificial intelligence applications for smart water systems. Water, 12(6), 1569.

9. SUEZ Group. (2023). Smart water management solutions.

10. 中国生态环境部. (2023). 中国工业废水再利用报告 [Report on industrial wastewater reuse in China]. (in Chinese).

11. 中国膜工业协会. (2024). 中国膜产业发展白皮书 [White paper on membrane industry development in China]. (in Chinese).